Applications

for safety catchers

Applications for safety catchers

Injection moulding machine (closing stroke protection)

Safety Catcher KR as closing stroke protection to protect the worker against unintended closing oft he mould. Such a protection is mandatory in the US and in Japan.

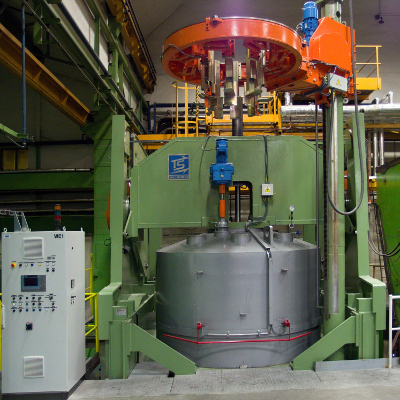

Hydraulic elevator

Safety Catcher for a hydraulic elevator to prevent that failures of the hydraulic system lead to accidents.

Broaching machine

Retaining the tool in case of a failure of the hydraulic system; safety for worker and machine.

Hydraulic press

Holding the press tool without a ratchet bar to prevent accidents due to hydraulic failures. Officially approved and certified acc. to ISO 16092 (ex EN 693).

Thermoforming press

Holding the press tool without a ratchet bar to prevent accidents due to hydraulic failures. Officially approved and certified acc. to ISO 16092 (ex EN 693).

Tyre curing press

Securing the tool to take out the finished tyres against falling down.

Hydroforming

Securing the press tool of a high pressure press for forming heat exchangers.

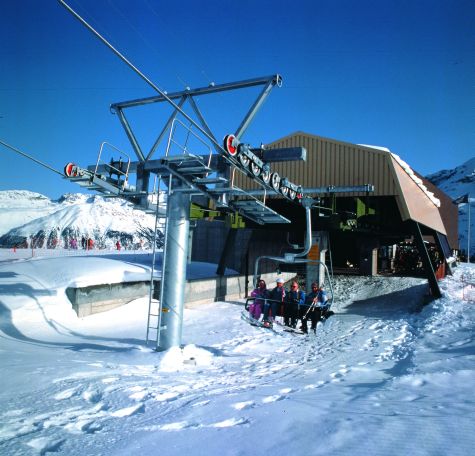

Aerial lift

Safety Catcher for the tensioning cylinder to keep the cable under tension in case the tensioning cylinder fails.

Trimming press

Securing of the vertical movement of the slide to prevent accidents due to hydraulic failures.

Packing machine

Securing the lifting frame driven by chains in a packing machine; safety for worker and machine in case of chain rupture.

Stack loader

The frame of this machine is lifted by chains. In case of chain rupture, the frame will be secured by a Safety Catcher acting on a separate holding rod.

Plastic moulding

Securing the upper mould in case of failure of the hydraulic system; safety for worker and machine.