PowerStroke

Generates large forces over short distances

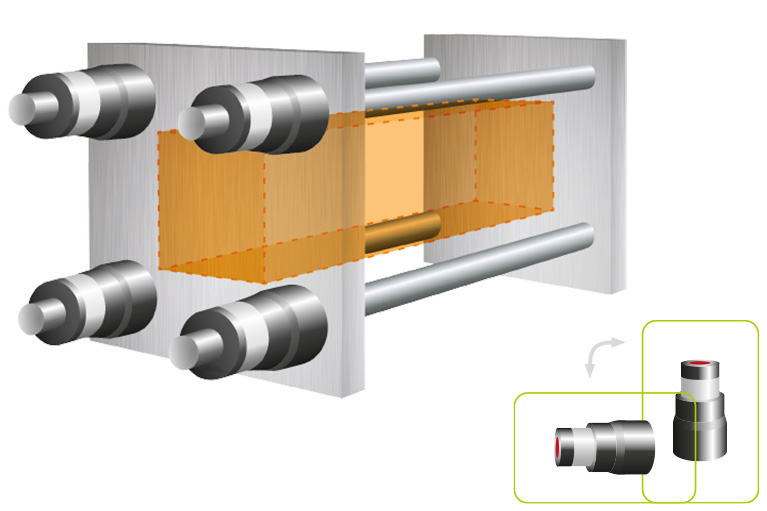

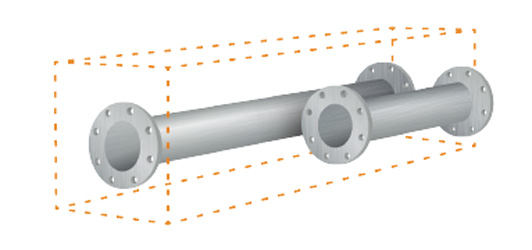

Clamping head with integrated short stroke function

The PowerStroke can be used in any horizontal and vertical applications requiring large forces to be built up over short working distances.

Series FSK, FSKP

- Clamping Head with additional integrated short stroke function

- Ideal for pressing, stamping, joining, riveting, clinching, forming, embossing, closing molds etc.

Fast stroke and power stroke: 2 features, 2 drives

Clamping Head with integrated short stroke cylinder

The PowerStroke mold closing device has been designed to hold and pull a clamping rod in one direction - the closing direction. It can be used in all applications that require powerful forces in a short working stroke. A single unit can apply forces of up to 180 metric tons; with the force being proportional to the applied pressure. This can be hydraulic (FSK series) or pneumatic (FSKP series).

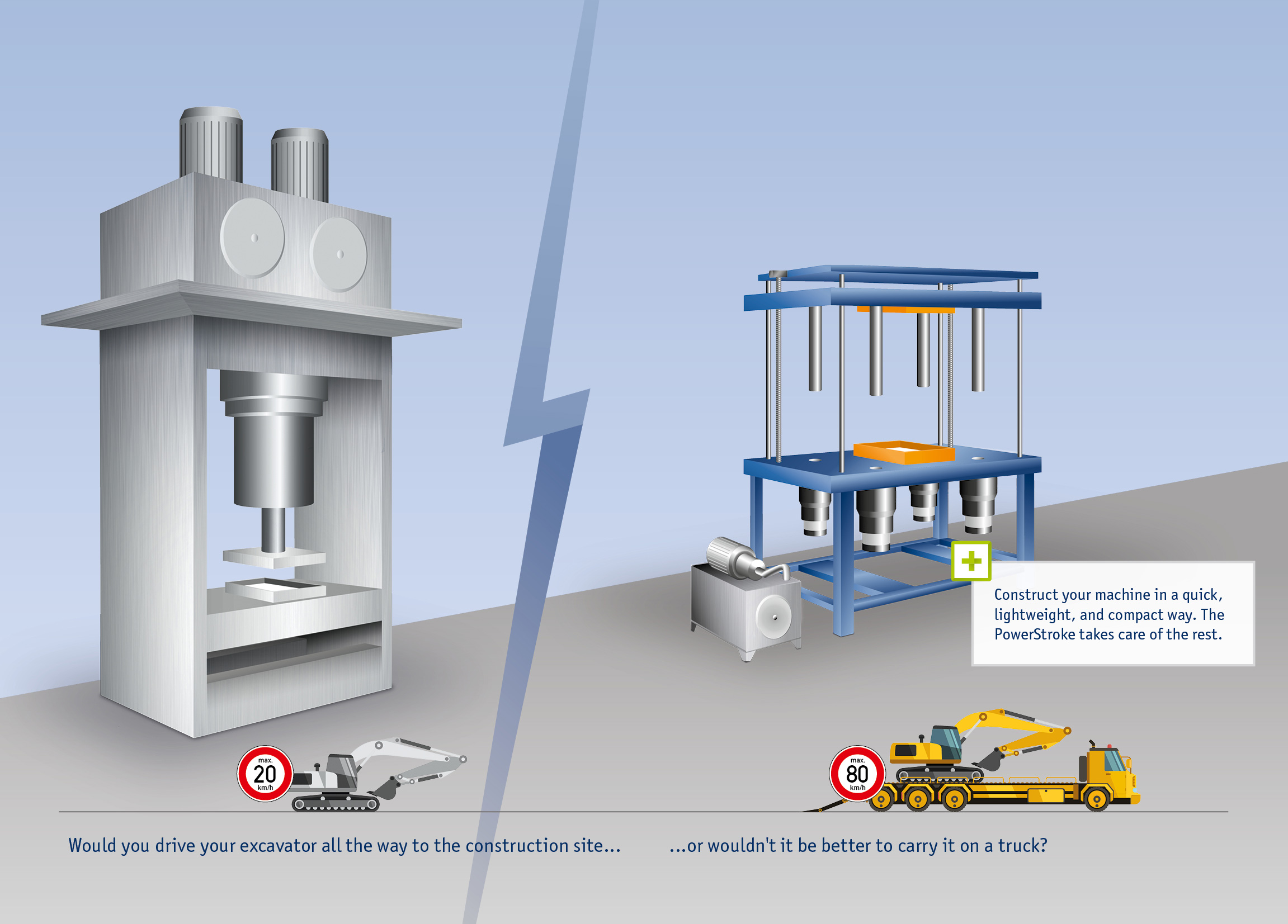

Split functionality is superior!

Produce fast and powerful movements with just one system? A weak compromise. The PowerStroke takes on the hard work with forces of up to 1800 kN. So you can use an efficient, compact, fast, and economic drive to open, close, and position molds or dies.

-

Function

Technical Data

Find outer dimensions, CAD files and technical data here.

Downloads

Why the PowerStroke is the better solution

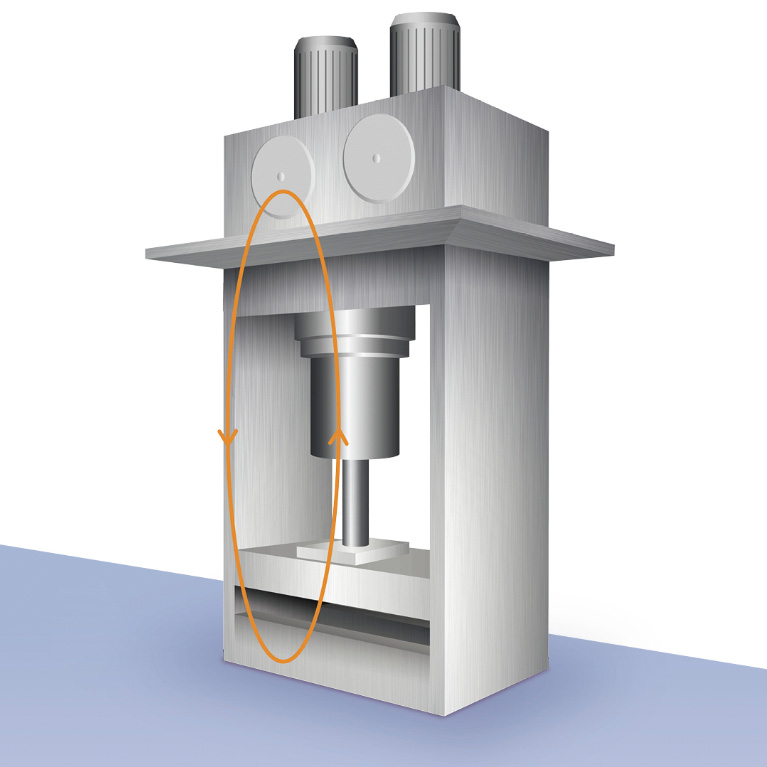

Inconveniences of a common press

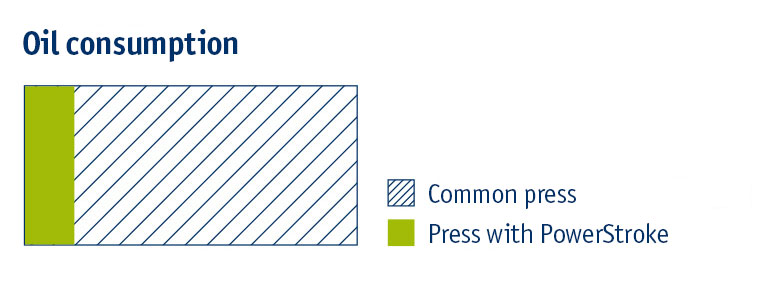

A press usually has a central press cylinder which generates both the power stroke and the opening and closing strokes. The same system generates the short power stroke on the one hand and the long opening and closing strokes which need only little power. As a consequence, the opening and closing strokes consume a lot of energy and are rather inefficient. Also the design of the machine frame is subject to significant limitations: The force the cylinder uses to press down has to be absorbed at the other end of the machine, i. e. the crosshead. As a consequence, this force affects the complete frame and machine portal; both have to be designed and built accordingly.

Advantages of a press with PowerStroke

The PowerStroke is the smarter and better solution! It generates the short power stroke right there where it is needed. As a consequence, the opening and closing strokes can be carried out by a compact, specialized drive system. Quickly and efficiently. Due to its intelligent design, the PowerStroke closes the mold by pulling instead of pressing as a press cylinder would do. Therefore, the closing force only affects the mold - not the complete machine frame. The press can be designed in a more compact way. Additionally, the compact design of both the PowerStroke and the drive system open new possibilities for construction. The rod can exit the PowerStroke and allow for a bigger working space. The PowerStroke operates very efficiently; therefore, the hydraulic units can be significantly smaller with less oil consumption. Also the power consumption can be reduced considerably.

- Force distribution in a confined space >

enables a lean, space-saving design - Low service needs >

due to durable components and easy replacement - Slim drive system >

reduction of costs of materials - Small hydraulic operating volume >

less energy consumption and costs - Clamping on hardened standard piston rods >

no complicated toothed racks required

What about your project?

Generate horizontal force?

The PowerStroke can operate vertically as well as horizontally. In both cases, at first a relatively big stroke has to generated with small forces. Then, for the last millimeters, great force has to be applied. After presenting the PowerStroke to our customers, we often hear: "If only I had known about this earlier!" Now you know. From now on, using the PowerStroke, you can design your machines in a more creative way.

Testing

- Leak test

- Load test

- Breaking test

Molding

- Castings

- Foam parts

- Injection molding

- Hydroforming

- High-volume presses

- Welding presses

Tasks

- Countering

- Holding down

- Fixing

- Boosting

Our know-how for your sustainability

Sustainability and mechanical engineering

In industry, big amounts of resources and energy are consumed; at the same time, there are big possibilities for saving. Realizing this potential not only leads to cost reductions but also demonstrates the ecological awareness of a company and can improve its public perception. We are very proud that we can make a contribution in this respect - to the benefit of our customers in the mechanical engineering industry and of the machine operators.

Sustainability and mechanical engineering

In industry, big amounts of resources and energy are consumed; at the same time, there are big possibilities for saving. Realizing this potential not only leads to cost reductions but also demonstrates the ecological awareness of a company and can improve its public perception. We are very proud that we can make a contribution in this respect - to the benefit of our customers in the mechanical engineering industry and of the machine operators.